Optimize your industrial air compressor monitoring with CAMLink™ Cloud Compressor Monitoring

In many industrial settings, individual air compressors often lack proper oversight, leading to undetected issues that can escalate into major problems, resulting in costly repairs and downtime. CAMLink™ Cloud Compressor Monitoring provides a comprehensive solution, bridging the gap by offering 24/7 cloud-based monitoring of your industrial air compressor performance.

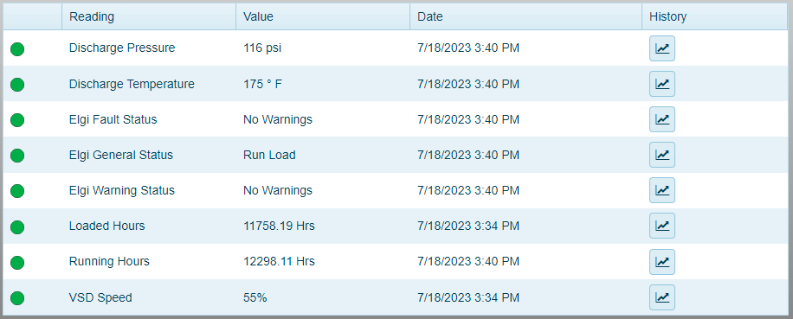

Say goodbye to unexpected downtime, lost production, unnecessary repair expenses, and premature component failure. With CAMLink™ Cloud Compressor Monitoring, CAST and your operations team can proactively track the health of each compressor running in your facility, gaining valuable insights into potential issues before they escalate. Our user-friendly interface features web-based dashboards and customizable alerts through text or email, keeping you informed about your compressed air system's status at all times.

CAMLink™ Cloud Compressor Monitoring not only identifies compressor health risks but also serves as a reminder for preventative maintenance tasks. The system generates custom alerts based on real-time data from your compressors, ensuring timely intervention. In the event of an alarm, CAST’s service team receives comprehensive information about the issue before arriving at your facility, streamlining the troubleshooting process upon arrival.

Compatibility is key – CAMLink™ Cloud Compressor Monitoring interfaces seamlessly with all compressor types, including rotary screw, centrifugal, and reciprocating. Regardless of the compressor manufacturer, if Modbus connectivity is available on the onboard controller, CAMLink™ Cloud Compressor Monitoring establishes a connection to collect essential air compressor data.

Choose CAMLink™ Cloud Compressor Monitoring to revolutionize your industrial air compressor oversight, preventing costly downtime and enhancing overall system efficiency.

CAMLink™ Cloud Compressor Monitoring not only identifies compressor health risks but also serves as a reminder for preventative maintenance tasks. The system generates custom alerts based on real-time data from your compressors, ensuring timely intervention. In the event of an alarm, CAST’s service team receives comprehensive information about the issue before arriving at your facility, streamlining the troubleshooting process upon arrival.

Compatibility is key – CAMLink™ Cloud Compressor Monitoring interfaces seamlessly with all compressor types, including rotary screw, centrifugal, and reciprocating. Regardless of the compressor manufacturer, if Modbus connectivity is available on the onboard controller, CAMLink™ Cloud Compressor Monitoring establishes a connection to collect essential air compressor data.

Choose CAMLink™ Cloud Compressor Monitoring to revolutionize your industrial air compressor oversight, preventing costly downtime and enhancing overall system efficiency.